Automatic concrete mixer Machine

Introduction

- Begin with a compelling statement about India’s incredible infrastructure growth and the reliance on efficient construction machinery like concrete mixers to meet rising demands.

- Highlight the importance of understanding the pricing dynamics, machine types, and regulations for contractors, small business owners, and construction professionals.

- Explain that this blog will provide a comprehensive guide covering market trends, types of machines, cost factors, regulations, maintenance tips, and future trends.

Body Sections

1. The Booming Indian Concrete Mixer Market

- Discuss the growth drivers of India’s construction industry, such as urbanization, Smart Cities initiatives, and infrastructure projects like highways and metro expansion.

- Highlight the increasing demand for concrete mixers with lift features, particularly for small-to-medium-scale construction projects.

- Mention growing trends, including automation and portable solutions, favored for their efficiency and cost-effectiveness.

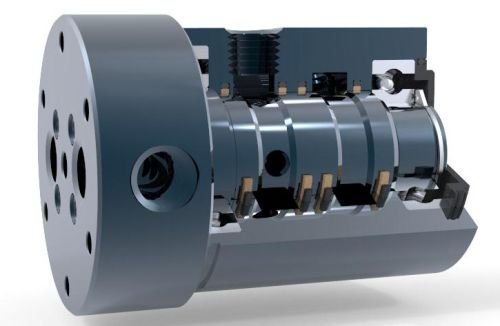

2. Types of Concrete Mixer Machines and Their Pricing

A. Overview of Key Mixer Types

- Portable Concrete Mixers with Lift

- Ideal for small-scale projects.

- Price range examples (e.g., INR X–Y) based on their capacity and features.

- Stationary Concrete Mixers with Lift

- Suitable for medium-level construction tasks.

- Price range (e.g., INR X–Y).

- Transit Mixers with Lift

- High-capacity, better suited for large construction sites.

- Pricing (e.g., INR X–Z).

B. Factors Affecting Prices

- Machine Capacity

- Outline how larger capacity correlates with higher costs.

- Brand

- Compare established brands like Universal or Venus with cost-effective local brands.

- Technology

- Explain how automation, sensors, and safety features influence price.

- New vs. Used

- Pros and cons of purchasing used versus new mixers.

3. Government Regulations and Their Impact on Pricing

- Overview of BIS standards that regulate quality and safety for concrete machinery.

- Discuss the role of schemes like MSME subsidies in reducing upfront costs for small-scale contractors.

- Cover GST implications on construction equipment pricing in India.

4. A Practical Buying Guide

A. Understanding Your Needs

- Identifying key usage requirements such as project size and typical workload.

B. Best Purchase Sources

- Mention reputable dealers, online platforms (e.g., IndiaMART), and trade expos.

- Highlight specific regional hubs popular for machinery, such as Coimbatore and Rajkot.

C. Evaluating Machine Quality

- Share tips to assess durability, operational efficiency, and overall reliability.

- Stress the importance of after-sales service and access to warranties.

D. Negotiation Tactics

- Provide strategies to secure the best deals, including group buying and negotiating additional perks like free delivery.

5. Maintenance Tips for Durability and Reliability

- Daily cleaning and lubrication guidance to prevent wear and tear.

- Importance of regular inspections to detect early signs of damage.

- Recommendations for using high-quality spare parts for replacements.

6. Innovations and Future Trends

- Overview of AI integration in newer models for improved operational efficiencies.

- Emerging eco-friendly solutions, including solar and hybrid-powered mixers.

- The rising prominence of IoT in machine monitoring and predictive maintenance.

7. Case Studies and Success Stories

- Share real-life examples of builders or contractors who used concrete mixers with lift features to improve project efficiency and reduce costs.

- Highlight ROI figures or tangible benefits from sourcing the right equipment.

Thought-Provoking Conclusion

- Summarize the critical points, reiterating the importance of identifying the right type of mixer, understanding pricing influences, and ensuring value through proper maintenance.

- Encourage readers to focus on long-term operational benefits rather than just upfront costs.

- Call-to-Action

- Invite readers to explore trusted sellers or connect with [Your Brand’s Team] for personalized advice on selecting the best concrete mixer for their needs.