Title

“Hand Piling Machines Demystified: Price Factors, Tips & Insights”

Introduction

- Begin with a brief explanation of what hand piling machines are and their role in construction projects.

- Highlight why understanding the costs of these machines is essential for professionals and project managers looking to budget effectively.

- Mention that the blog will cover the key factors affecting hand piling machine prices, a general price range, and practical tips for making an informed purchase.

Body Sections

1. What Are Hand Piling Machines?

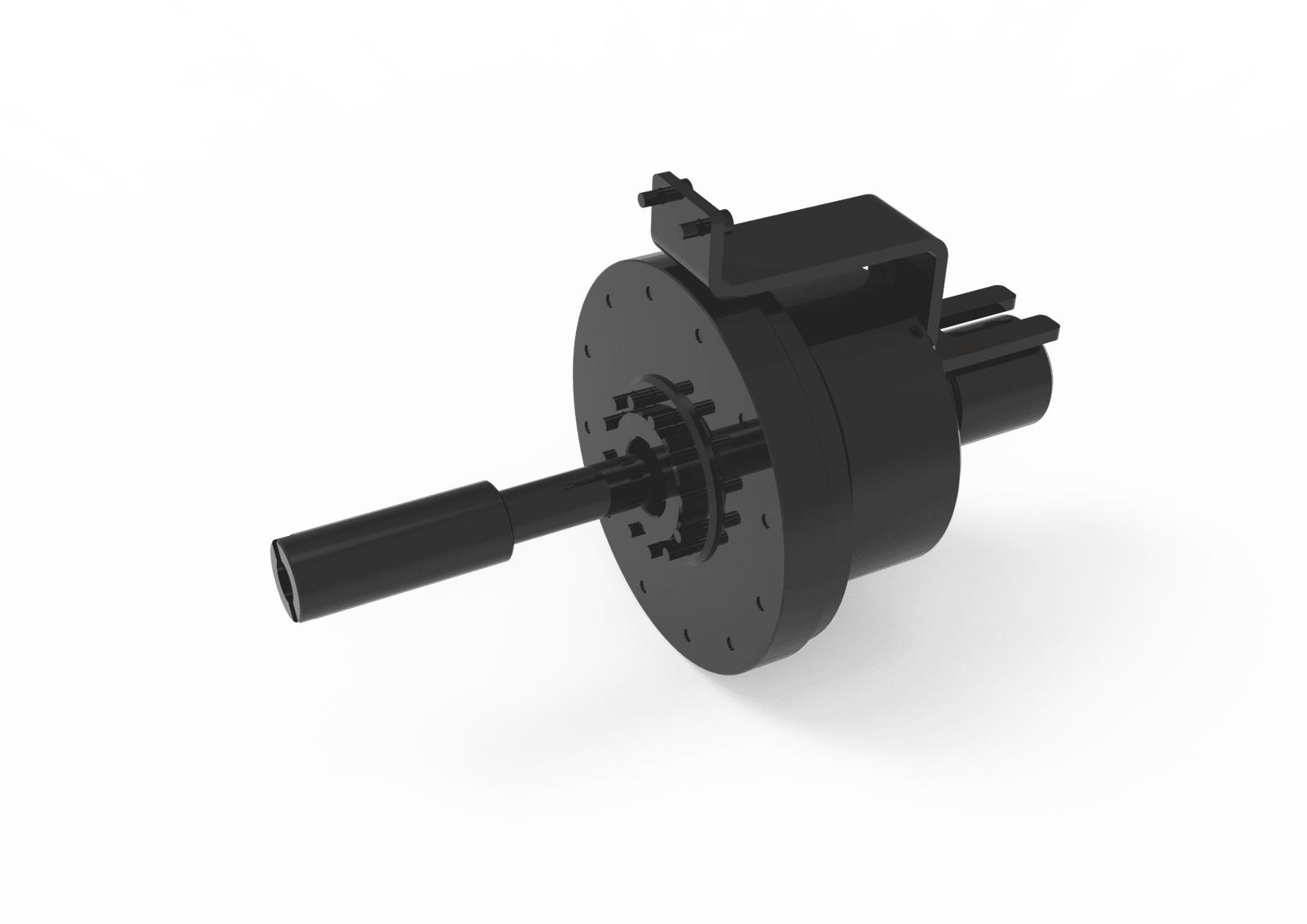

- Provide a short definition and the purpose of hand piling machines in construction.

- Mention common use cases, such as laying strong foundations for buildings or infrastructure.

2. Factors Affecting Hand Piling Machine Price

The cost of hand piling machines can vary based on several factors. Below are the most significant considerations:

a. Machine Capacity and Size

- Explain how machine strength and load handling capacity impact pricing.

- Discuss how larger or higher-capacity machines are typically priced higher due to their advanced functionality.

b. Material Quality and Durability

- Explore how top-quality materials, like heavy-duty steel, contribute to higher costs but are more reliable for long-term use.

c. Technological Features

- Note the role of advanced features such as automation, digital controls, and portability in determining cost.

d. Brand Reputation and Warranty

- Explain how established brands with trusted reputations often charge premium prices.

- Stress the importance of checking warranty benefits as an indicator of long-term value.

e. Customization Options

- Highlight that custom features or modifications can significantly impact price to meet unique project needs.

3. Hand Piling Machine Price Range Overview

- Provide an approximate price range for different types of hand piling machines, catering to entry-level, mid-tier, and premium buyers.

- Break down examples to target varied budgets (e.g., $1,000–$3,000 for basic machines, $5,000+ for premium models with advanced features).

4. Tips for Buying a Hand Piling Machine

a. Define Your Needs

- Recommend buyers assess their specific project requirements (e.g., capacity, space constraints).

b. Comparison Shopping

- Advise comparing models and prices from different manufacturers or distributors.

- Mention the benefit of using online platforms or trade fairs for research.

c. Check After-Sales Services

- Stress the importance of choosing brands with accessible after-sales services and readily available spare parts.

d. Evaluate User Reviews

- Suggest researching customer reviews or seeking peer recommendations for trustworthy brands and models.

Thought-Provoking Conclusion

- Summarize key insights, emphasizing the need to consider factors like machine capacity, material quality, and brand reputation when evaluating prices.

- Reinforce the idea that buyers should prioritize value over the lowest price to ensure efficiency and durability in their projects.

- Encourage readers to take the next step by reaching out to industry experts or exploring available models online. Offer a gentle nudge to review top brands or suppliers relevant to their needs.

SEO Suggestions

- Title:

- Place “Hand Piling Machine Price” near the beginning of the title to target the keyword effectively.

- Introduction:

- Include “hand piling machine price” within the first 100 words to help readers and search engines recognize the blog’s topic early on.

- Body Sections:

- Naturally integrate the keyword in section titles like “Factors Affecting Hand Piling Machine Price” and “Hand Piling Machine Price Range Overview.” Avoid overusing the keyword; focus on using natural synonyms like “cost of hand piling machines.”

- Meta Description:

- Title

“Hand Piling Machines Demystified: Price Factors, Tips & Insights”

Introduction

Begin with a brief explanation of what hand piling machines are and their role in construction projects.

Highlight why understanding the costs of these machines is essential for professionals and project managers looking to budget effectively.

Mention that the blog will cover the key factors affecting hand piling machine prices, a general price range, and practical tips for making an informed purchase.

Body Sections

1. What Are Hand Piling Machines?

Provide a short definition and the purpose of hand piling machines in construction.

Mention common use cases, such as laying strong foundations for buildings or infrastructure.

2. Factors Affecting Hand Piling Machine Price

The cost of hand piling machines can vary based on several factors. Below are the most significant considerations:

a. Machine Capacity and Size

Explain how machine strength and load handling capacity impact pricing.

Discuss how larger or higher-capacity machines are typically priced higher due to their advanced functionality.

b. Material Quality and Durability

Explore how top-quality materials, like heavy-duty steel, contribute to higher costs but are more reliable for long-term use.

c. Technological Features

Note the role of advanced features such as automation, digital controls, and portability in determining cost.

d. Brand Reputation and Warranty

Explain how established brands with trusted reputations often charge premium prices.

Stress the importance of checking warranty benefits as an indicator of long-term value.

e. Customization Options

Highlight that custom features or modifications can significantly impact price to meet unique project needs.

3. Hand Piling Machine Price Range Overview

Provide an approximate price range for different types of hand piling machines, catering to entry-level, mid-tier, and premium buyers.

Break down examples to target varied budgets (e.g., $1,000–$3,000 for basic machines, $5,000+ for premium models with advanced features).

4. Tips for Buying a Hand Piling Machine

a. Define Your Needs

Recommend buyers assess their specific project requirements (e.g., capacity, space constraints).

b. Comparison Shopping

Advise comparing models and prices from different manufacturers or distributors.

Mention the benefit of using online platforms or trade fairs for research.

c. Check After-Sales Services

Stress the importance of choosing brands with accessible after-sales services and readily available spare parts.

d. Evaluate User Reviews

Suggest researching customer reviews or seeking peer recommendations for trustworthy brands and models.

Thought-Provoking Conclusion

Summarize key insights, emphasizing the need to consider factors like machine capacity, material quality, and brand reputation when evaluating prices.

Reinforce the idea that buyers should prioritize value over the lowest price to ensure efficiency and durability in their projects.

Encourage readers to take the next step by reaching out to industry experts or exploring available models online. Offer a gentle nudge to review top brands or suppliers relevant to their needs.

SEO Suggestions

Title:

Place “Hand Piling Machine Price” near the beginning of the title to target the keyword effectively.

Introduction:

Include “hand piling machine price” within the first 100 words to help readers and search engines recognize the blog’s topic early on.

Body Sections:

Naturally integrate the keyword in section titles like “Factors Affecting Hand Piling Machine Price” and “Hand Piling Machine Price Range Overview.” Avoid overusing the keyword; focus on using natural synonyms like “cost of hand piling machines.”Image Optimization:

Use alt text in images, such as “Examples of hand piling machine price comparisons” to enhance SEO further.

- Image Optimization:

- Use alt text in images, such as “Examples of hand piling machine price comparisons” to enhance SEO further.