Borewell drilling pipe length

Borewell Drilling Pipe Length: Standard Sizes, Types & Buying Guide

Borewell drilling pipes are an essential component in groundwater extraction systems across agricultural, domestic, and industrial applications. Choosing the correct borewell drilling pipe length is crucial for ensuring long-term durability, cost-effectiveness, and consistent water output.

In this blog, we’ll break down the standard borewell pipe lengths, types, applications, and factors to consider when selecting the right pipe for your drilling needs.

Focus Keyword: Borewell Drilling Pipe Length

LSI Keywords: Borewell pipe size, Borewell casing pipe

What is the Standard Borewell Drilling Pipe Length?

In India, the standard length of a borewell drilling pipe typically ranges from 3 meters (10 feet) to 6 meters (20 feet). These pipes are connected through threaded joints or couplings, allowing flexibility in adjusting the total depth based on the water table and borewell specifications.

Common Pipe Lengths:

- 3 meters (10 feet) – used in manual or shallow borewells

- 4.5 meters (15 feet) – moderate depth applications

- 6 meters (20 feet) – preferred in deep borewell drilling

Note: The final pipe length used depends on the depth of drilling, soil condition, and borehole diameter.

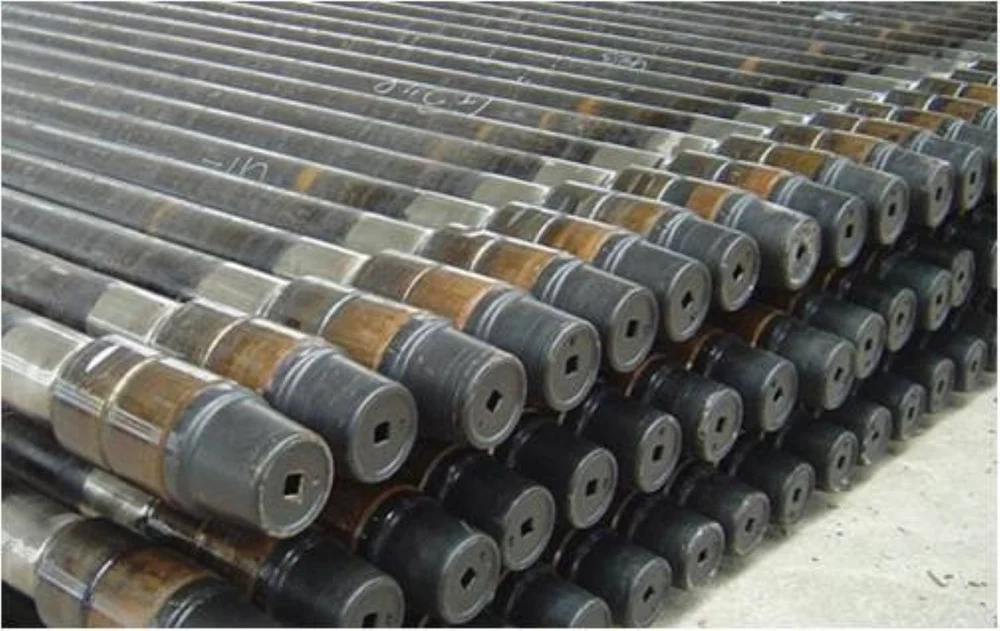

Types of Borewell Drilling Pipes

1. MS (Mild Steel) Borewell Pipes

- High strength and pressure resistance

- Ideal for deep borewells (up to 1000 ft and more)

- Standard length: 20 ft (6 meters)

2. PVC Borewell Casing Pipes

- Lightweight and corrosion-resistant

- Suitable for shallow to medium-depth borewells

- Available in 2.5 to 6-meter lengths

3. HDPE Borewell Pipes

- Flexible and durable under high pressure

- Typically used for agriculture and irrigation

- Common length: 3 or 6 meters

Factors Affecting Borewell Pipe Length Selection

Here are key factors to consider:

- Depth of the Borewell – Deeper wells require longer pipes and high tensile strength.

- Type of Soil/Rock Formation – Rocky terrain may need stronger steel pipes.

- Water Table Level – Determines how much pipe length must go below the surface.

- Casing Pipe Requirements – For unstable soils, longer casing pipes are needed.

- Pipe Jointing Method – Length may vary based on threaded or socket-type joints.

Comparison Table: Borewell Pipe Lengths by Type

| Pipe Type | Material | Standard Lengths (m) | Depth Range | Application Type |

|---|---|---|---|---|

| MS Drilling Pipe | Mild Steel | 6 m (20 ft) | Up to 1000 ft+ | Deep borewells, industries |

| PVC Casing Pipe | uPVC | 3–6 m | 50–300 ft | Residential, casing use |

| HDPE Pipe | Polyethylene | 3 or 6 m | 30–400 ft | Agriculture, irrigation |

Where to Buy Borewell Drilling Pipes?

Look for trusted suppliers who offer:

- ISI-marked or BIS-approved pipes

- Custom pipe lengths as per project

- On-site delivery & thread-cutting service

- Technical support for bore depth calculation

Internal Links:

Call to Action

Choosing the right borewell drilling pipe length can improve water yield and system longevity. Our team can help you choose the right material, grade, and length based on your soil and depth requirements.

Get a Quote Now

Email: info@titansteel.in / sales@titansteel.in

Phone: +91 738 586 3226

Address:H No. 181, Dahivali, Khopoli-Pali road, Tal. Khalapur Dist. Raigad 410203, Maharashtra INDIA.